- Posted in: White Papers & Case Studies

- By ProMed Staff

Introduction

In 2006, ProMed embarked on a journey to broaden our capabilities from the molding and assembly of components for medical devices to include the manufacturing of drug/device combination products. Differences in regulatory requirements between medical devices and pharmaceutical products presented unique challenges during this effort across the company to meet our customers’ and regulatory bodies’ stringent quality, safety, and compliance goals. This whitepaper discusses the challenges ProMed Pharma has confronted in three key areas: facility design, implementing the Pharma Quality System, and company culture for the enhanced scrutiny that accompanies these products. We also discuss the solutions that ProMed Pharma has enacted to meet these challenges.

Challenge 1: Facility Design

Prior to bringing a new manufacturing process online, it is essential to establish a close collaboration between the customer and the ProMed team to understand and define the intended flow of materials, personnel, and equipment in the facility. Once these are understood, the needs of the facility can be summarized in a mutually agreed upon User Requirements Specification (URS) describing the necessary features that must be designed into the facility and validated to ensure those needs are met. These requirements are then translated into specific designs addressing each requirement by implementing appropriate-sized production areas, layouts, equipment, utilities, and safety precautions. Each can then be validated appropriately to ensure that all the requirements established for the facility in the URS have been met.

Much of this approach is shared with ProMed’s molded components facilities, but several areas are of particular concern when designing facilities for combination products:

1) Receipt, Storage and Testing of Raw Materials

Drug substances and excipients must be received, quarantined, sampled, tested, and released prior to use. Additionally, to ensure personnel are properly protected from hazardous drug substances, each drug substance’s Occupational Health Toxicity/Potency Category, Safety Data Sheet, and other available information are evaluated and a mitigation plan determined. Appropriate personal protective equipment such as respirators and isolators are then used during receiving, sampling, and manufacturing.

Prior to receipt of raw materials, documents establishing the sampling required for these materials are written, reviewed, and released into the ProMed Pharma Quality System. Upon receipt of material, these documents are consulted to verify material certificates comply with pre-established specifications and what tests must be performed. Generally, identity testing, purity, strength, and quality must be confirmed. Prior to release to the manufacturing floor, these records documenting the sampling, testing, and release are completed, verified to meet materials specifications, and reviewed. Please refer to our follow-on article, The Challenges of Manufacturing Combination Components Part 2 for further guidance.

Throughout this process, it is essential that incoming materials are segregated in quarantine away from released material that has already been verified as suitable for use. These quarantine areas must have appropriate temperature, light, and humidity conditions to assure continued quality during testing and release. To ensure that this is the case, ProMed established a series of labeled, segregated cages, coolers, and freezers with temperature control, monitoring, and qualification for their intended use beyond those already in place for storing materials for use in manufacturing. To help ensure that unreleased materials are never used, we formalized and expanded our existing system of color-coded materials labeling for each stage of receipt, quarantine, and acceptance to supplement physical segregation in our cages, coolers, and freezers.

2) Cleanroom space, utilities, and equipment for manufacturing

To ensure that all requirements established at the outset of a project are met to the satisfaction of our customers and regulatory bodies, it is essential that the equipment, air handling, process flow, cleanroom layout, and utilities are considered and established as new pharma production facilities.

Each product has very different requirements that require careful consideration during design of the manufacturing facility. For example, the facilities needed for manufacturing an ocular implant containing minute quantities of drug tend to be quite different from those for large scale manufacture of an intravaginal ring that consumes kilograms of potent hormone per batch. To ensure proper materials and personnel flow, each cleanroom is tailored to the needs of a particular customer and product.

Equipment and process requirements are evaluated for appropriate size, required utilities, materials of construction, monitoring instrumentation, pressure gauges, temperature gauges, and any other equipment particular to the product. While specifying equipment, the available utilities are compared to the actual daily consumption and demand for these items and what additional usage is expected when installed in the facility. When necessary, utilities are upgraded or modified to suit the needs of the specified equipment. In cases where the utility has a direct or indirect impact upon product quality, validation testing is performed to verify quality during this operation. For example, ProMed uses compressed air both to drive actuators and remove materials. In the former case, the validation is focused on maintaining pressure and variability within pre-established limits. In the latter case, the compressed air contacts product; as a result, validation is expanded to ensure that no oils, moisture, or microbial contaminants are present. Similarly, if a Purified Water System is used to wash components it therefore needs to be validated to ensure that the water meets USP requirements.

Careful specification and validation of air handling units (AHUs) is a major feature in the design of pharma production facilities. Proper air exchanges, pressure differentials between clean and dirty areas, minimization of operator exposure to drug substances, and maintenance of the proper humidity and temperature levels are all critical design criteria that must be handled by these units. To ensure our facilities continuously operate within specified conditions, an industry-leading electronic Building Automation System (BAS) was installed and validated. The BAS provides continuous remote monitoring and control of pressure differentials, temperature, and humidity to ensure that production areas remain within specified limits for each area.

ProMed’s typical pharma production facility is an ISO Class 7 cleanroom suite dedicated to a particular customer. We prefer to build our cleanroom suites with two air handler units, one that serves the main manufacturing areas and a dedicated unit for our mixing rooms. The dedicated unit helps to ensure drug particulates generated during the mix process are not recirculated into the main cleanroom. Additionally, we design our facilities so that the mix room has a negative pressure differential to adjacent rooms, so drug particulates generated during the mix process do not escape to the main manufacturing area or areas outside of the cleanroom suite. When appropriate, a series of pressure differentials can be maintained within the sub-rooms of a particular suite to ensure appropriate cleanliness and flow for each space.

3) Facility Qualification and Validation

As each new manufacturing facility is brought online, Design Qualification (DQ) is performed to ensure the cleanroom suite has been built to meet the specifications initially agreed upon in the URS. Validation of the suite includes Installation Qualification (IQ), Operation Qualification (OQ), and Performance Qualification (PQ) testing to ensure the cleanroom and Air Handler Units have been installed and operate as expected, proper air changes per hour are achieved, room balancing requirements have been met, all HEPA filters passed leak testing, and the room passed ISO 7 particle classification.

Once the facility has been initially qualified, the facility is placed into an environmental monitoring program. The new cleanroom suite is thoroughly cleaned in accordance with cleanroom cleaning and sanitization procedures. Once cleaning has been completed and documented, initial testing includes a three-consecutive-day period where no operators are present (static testing) followed by a three- consecutive-day period where operators are present (dynamic). The airborne viable microorganism, surface microorganism, and non-viable particulate levels from this initial testing are used to establish a baseline and the initial alert and action levels. The facility is then added to our routine Environmental Monitoring (EM) program and sampling is performed quarterly.

ProMed typically dedicates process and in-process test equipment to a particular drug substance. This helps to minimize subsequent cleaning validation requirements. All pieces of equipment used in the process are evaluated through a risk-based process for validation requirements. Where appropriate, equipment is IQ/OQ and PQ qualified before Process Validation (PV) and all operators working in the manufacturing operations are trained to the process.

Process Validation is performed by Process Operation Qualification (POQ) where at least three production runs are performed to confirm the upper and lower process limits. The POQ helps to establish process control schemes and guard banding. Once the POQ is satisfactorily complete, three consecutive Process Performance Qualification (PPQ) runs at the process center points are performed to verify process capability and the appropriateness of the established control schemes.

Challenge 2: Quality System

When ProMed embarked on manufacturing Combination Products nearly a decade ago, few specific combination product regulations existed. To develop a new combination device Quality System, our existing ISO 13485 certified Medical Device Quality System was used as a base augmented with the applicable drug requirements.

To create the Pharma Quality System, ProMed compared it’s existing system to available guidance, particularly FDA’s draft guidance “Good Manufacturing Practice for Combination Products” and Medical Devices Quality Management Systems – “Guidance on Application of ISO 13485.” This led to significant additions to the existing system, particularly with regard to training, documentation, testing, and record management. This new Pharma Quality System was then implemented as a separate, sister system for combination devices to the existing ProMed Quality system; in this way we have been able to ensure full compliance for each portion of the company while continuing to ensure rapid and cost-effective delivery of non-drug components.

Since the initial implementation of this system, we have continued to modify and update the Quality System to reflect current guidance. In the intervening years the FDA has recognized industry’s struggle with regulatory expectations and in January 2013 issued the final rule for 21 CFR Part 4, cGMP Regulation of Combination Products, and the Final Guidance for Industry on how to comply with these new requirements was published in January 2017. As it is commonly referred to today, Part 4 instructs those companies making Combination Products to fully comply with either a Device-based Quality System or a Pharma-based Quality Management System and augment it with the procedures necessary to support either a pharma product or a device product. ProMed’s approach to compliance in-depth is explored in a second article on The Challenges of Manufacturing Combination Components – Part 2.

Challenge 3: Standards and Culture

The cultural shift necessary to move from manufacturing molded components to successfully manufacturing combination products has been a major area of focus for ProMed Pharma. Some basic assumptions about how products are made, moved, and documented needed to be changed as part of this shift. Several of these are discussed below.

1) Batch Processing

In much of the medical device contract manufacturing industry, batch size for a particular lot corresponds with the number of components processed through the manufacturing environment. As parts pass through a particular operation, process and yield data are recorded for the entire lot.

In contrast, for combination device manufacturing, manufacturing often consists of a series of discrete processing steps where key characteristics (weight, yield) of individual units are tracked. Often these characteristics act as in process controls to assure the quality of the product through each step of manufacturing and assure the correct amount of drug is incorporated into the manufactured component. To implement this shift, ProMed adopted a manufacturing process where yield and processing steps can be addressed in a granular manner throughout manufacture of a particular batch. For some particularly demanding products, this tracking has been sufficiently careful to allow tracking of sub-batches as small as 8-16 parts made in a single injection cycle from thousands in a production lot, with each of these sub-batches tracked through the manufacturing process. By documenting and trending key measurements through each phase of manufacture we are able to assure continued product quality and rapidly diagnose the source of any potential out of specifications results quickly and thoroughly. This allows more precise tracking of yield through the manufacturing process and reconciliation of drug substance for each batch.

2) Documentation and Company Culture

ProMed’s experience in medical device contract manufacturing provided a thorough understanding of the importance of the accuracy of device history records and associated documentation. Moving into combination products, we were challenged to take on another level of diligence to assure that we properly document every aspect of our work. This required a concerted and ongoing training program to ensure that employees from the newest operator to senior management were indoctrinated in the necessity of the additional documentation, conversant in the additional requirements required, and capable of withstanding the higher level of scrutiny expected. To ensure our ability to meet these more stringent standards of documentation in parallel, we have steadily expanded our QA staff to help ensure progressive compliance and ensure the timely and complete review of our records.

This emphasis on high documentation standards has had a synergistic effect on ProMed’s molded products division. As we endeavor to build best practices and standards for ProMed Pharma, many of these policies and procedures have been implemented companywide, enhancing customer value and providing higher assurance of quality. The process is an ongoing one. As part of our document review and training programs, we continue to implement best practices and incorporate updated regulatory requirements to ensure the highest levels of quality and compliance.

3) Understanding Value

Due to the incorporation of higher-cost constituents including Active Pharmaceutical Ingredients (APIs) and the higher degree of control required for manufacturing, combination devices rapidly became among the highest value parts manufactured at ProMed. While these parts may at first glance seem similar to parts our operators make every day from more conventional materials, the additional value of these components required a shift in practices. To ensure that materials were used and tracked effectively, additional education was necessary so operators could more fully understand the scope and added value for these parts. In addition, more rigorous training was implemented on each step of manufacturing to ensure that operators could more effectively execute the process. As a result, scrap was reduced as yields and reconciliation values increased.

4) Employee Flexibility

ProMed initially chose to use its workforce from existing component manufacturing areas during our first forays into manufacturing Combination Products. This required that the operators move between quality systems, batch processing approaches, and working with variable parts from day to day. To make this possible, feedback systems were implemented to monitor the performance of the operators, the process, and quality.

To help operators adjust to the new requirements, a flexible work schedule was implemented where personnel could enter the new environment at a level suitable to their level of experience. Coupled with existing performance metrics this allowed for a combination of self-selection for this more demanding manufacturing environment and identification of those operators who most consistently met the more stringent requirements of combination components, which allowed ProMed Pharma to steadily build a versatile work force capable of successfully manufacturing combination products, understanding the importance of pharma quality requirements, and exercising the diligence and attention to detail needed when completing rigorous manufacturing, testing, inspection, and release documentation.

Conclusion

With a dedicated Quality System, purpose-build cleanroom facilities, and experienced, capable employees, ProMed Pharma has met the challenges associated with manufacturing Combination Products. In the process, ProMed Pharma has been proven capable of consistently supplying quality products to a range of pharmaceutical and device partners. This has required a dedicated and ongoing effort across several fronts discussed in this paper.

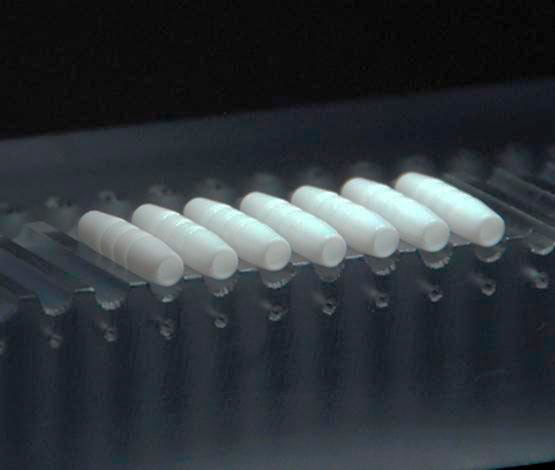

Today, ProMed Pharma is well-positioned to actively support new partners and shorten the time required for market launch. With expertise in Combination Products, including drug eluting vaginal rings, ophthalmological implants, and diabetes monitoring systems, combined with extensive medical device manufacturing knowledge and experience, has added great value to ProMed Pharma’s customers from the planning stage through regulatory submission to sustainable manufacturing.

The Challenges of Manufacturing Combination Components Part 2