Role and Importance of Metrology in Silicone Injection Molding

Measurement is fundamental to the success of a silicone injection molding company. In this industry, where parts often feature complex geometries and must adhere to stringent tolerances, precise measurement and inspection are essential to ensure part quality, consistency, and compliance with exact specifications.

Silicone components, which may be soft, flexible, or translucent, pose unique measurement challenges due to their material properties and intricate designs. Advanced metrology ensures that each part meets customer requirements and industry standards, guaranteeing functionality, reliability, and satisfaction while reducing the risk of defects that could lead to product failures or costly rework.

Advanced Metrology Technologies in Use

To meet these demands, ProMed employs a suite of sophisticated metrology technologies, each tailored to address specific measurement needs:

• Computed Tomography (CT): This non-destructive technology provides detailed internal inspection and dimensional analysis, making it ideal for soft or complex silicone parts. CT scans reveal hidden features like internal cavities or channels without damaging the component, ensuring that intricate internal and external structures meet design specifications.

• Optical 2D Inspection: Optical 2D inspection is a non-contact measurement technique that captures high-resolution images to evaluate the dimensions and surface features of silicone products, making it ideal for verifying part geometry without deforming soft or flexible materials.

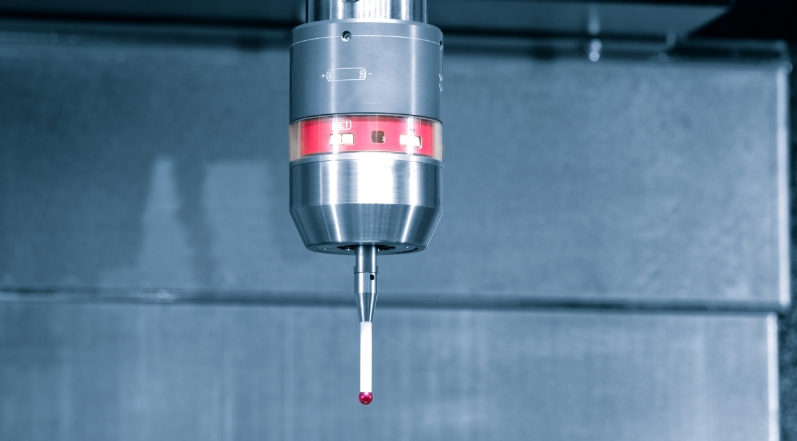

• Tactile Measurement (CMM): Utilizing Coordinate Measuring Machines (CMMs), this contact-based approach offers high-precision dimensional verification. CMMs confirm critical dimensions with exceptional accuracy, ensuring compliance with tight tolerances, especially for molds.

• Chromatic White Light Inspection: A chromatic white light sensor, which utilizes chromatic aberration to measure surface distances via the wavelengths of reflected light, enables non-contact measurement of freeform surfaces and transparent parts, excelling on materials that are sensitive, reflective, or low-contrast, where other optical sensors may struggle.

In conclusion, metrology plays a vital role in silicone injection molding by ensuring rigorous quality control through accurate measurement and inspection. By utilizing advanced technologies such as CT scanning, Optical 2D Inspection, Tactile Measurements, and Chromatic White Light Inspection, ProMed consistently delivers high-quality parts, streamlines production, and minimizes waste—meeting the stringent requirements of complex silicone components.